XH&SILVER Jewelry Manufacturing

Deliver high-quality custom 925 sterling silver jewelry, meeting global demand. We offer both large-scale and small-batch production solutions, ensuring flawless results while promoting sustainable development.

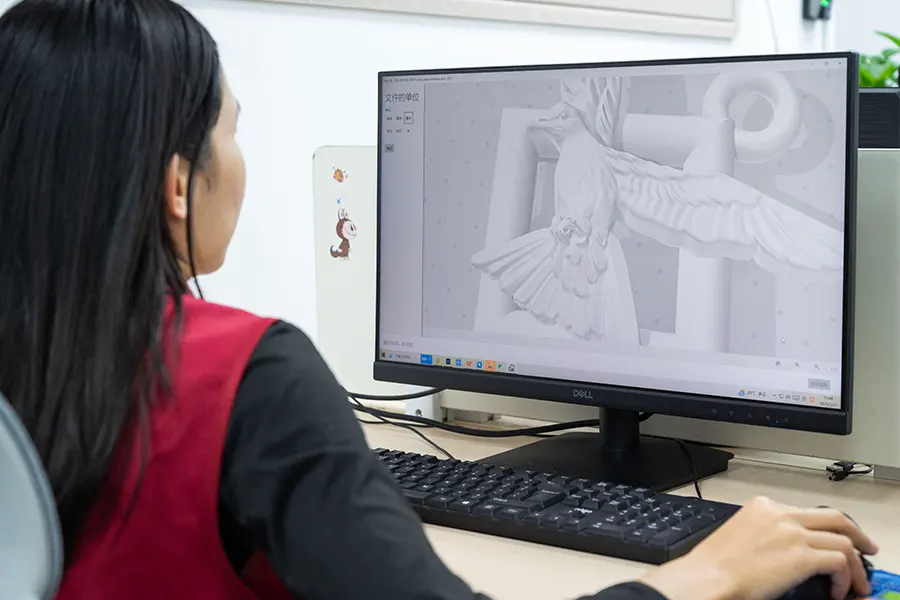

Advanced Manufacturing Facility

Equip with advanced technology like CNC, 3D printing, and laser engraving for precise jewelry production.

Our Jewelry Manufacturing Process

At XH&SILVER, we focus on every detail, from sourcing materials to delivering the final product. Our manufacturing process adheres to the highest quality standards to ensure that each piece of 925 sterling silver jewelry meets our clients’ expectations.

Stage 1:

Mould Creation

At XH&SILVER, we focus on every detail, from sourcing materials to delivering the final product. Our manufacturing process adheres to the highest quality standards to ensure that each piece of 925 sterling silver jewelry meets our clients’ expectations.

Jewelry Design & Model Creation

Creation of Wax Model

Wax Tree Formation

Plaster Mold Creation

The wax models are attached to a wax tree, with multiple models added to create a full structure for efficient casting.

Burnout Process

The wax models are attached to a wax tree, with multiple models added to create a full structure for efficient casting.

Stage 2:

Silver Casting

This stage is where the silver is prepared and poured into the molds. The metal is melted to the right temperature and then carefully poured into the molds to create the jewelry pieces. Casting requires precision to ensure the shapes and designs are replicated perfectly.

Metal Pouring

Silver Casting

Casting Completion

Cleaning & Residue Removal

Stage 3:

Finished Jewelry Manufacturing

The final stage focuses on refining the jewelry pieces. This includes cutting, grinding, stone setting, polishing, and quality control, all of which are necessary to ensure the jewelry pieces meet high standards of craftsmanship, aesthetics, and functionality.

Cutting & Refining

Grinding & Smoothing

Stone Setting

Jewelry Polishing

Final Cleaning

Final QC & Packaging

Quality Control & Assurance

At XH&SILVER, we focus on every detail, from sourcing materials to delivering the final product. Our manufacturing process adheres to the highest quality standards to ensure that each piece of 925 sterling silver jewelry meets our clients’ expectations.

Raw Material Inspection

Precious Metal Testing:

Test the purity and weight of precious metals such as gold, silver, platinum, and palladium to ensure they meet required standards.

Gemstone Testing:

Test the authenticity, color, clarity, and weight of gemstones, including natural stones, synthetic gems, and pearls, to ensure their quality and authenticity.

In-Process Inspection

Semi-Finished Product Inspection:

Inspect semi-finished products at each stage of production to ensure quality and identify any defects before proceeding to the next phase.

Stone Setting Inspection:

Ensure that gemstones are securely set, accurately positioned, and free from scratches or defects, preserving the integrity of the design.

Finished Product Inspection

Appearance & Specification Check:

Inspect the finished product for surface smoothness, gemstone setting security, and measure dimensions and weight to ensure conformity with design specifications.

Functionality Testing:

Perform functionality tests, such as checking ring closures and necklace clasps, to ensure ease of use and reliable operation.

Hallmark and Label Inspection

Hallmark Check:

Verify that precious metal hallmarks are clear, complete, and appropriately placed, including the manufacturer’s code, material type, purity, and diamond weight.

Label Inspection:

Ensure that labels are accurate and complete, including details such as material type, purity, product name, weight, standard codes, and certification.

Certification & Packaging Inspection

Certificate Verification:

Verify that the certificate details match the actual product, ensuring the certificate type, number, and photos are clear and accurate.

Packaging Integrity and Information Check:

Check that packaging is intact and undamaged. Verify that packaging information matches the product, including brand name, product model, and material type.

Final Quality Review

Sampling Inspection:

Conduct random sampling of products from a batch to perform comprehensive quality checks, ensuring overall product quality.

Quality Report:

Generate a final quality report documenting all inspection results and any issues found. Non-compliant items are either reworked or discarded to ensure that only high-quality products leave the facility.

Final Inspection

Delivery to Logistics:

Ensure that approved products are handed over to the logistics company for safe and timely shipping to clients.

Sustainable Manufacturing

We are committed to sustainable manufacturing. By using recycled metals, energy-efficient equipment, and eco-friendly processes, we minimize our environmental impact. Our facilities continuously optimize production methods to ensure the lowest energy consumption and waste emissions.

Certified Gemstones

Recycled Metals

Energy-Efficient Manufacturing

Waste Reduction

Best Choice of Your 925 Silver Jewelry Business

Renewable Material

We embrace sustainability, using recyclable materials in energy-efficient factories without compromising quality.

One-stop Customization

From sketch to final product, we offer full support with zero design fees, deducted after order confirmation.

Rapid Response

Respond swiftly in 24h to your inquiries, stay closely connected, and deliver products efficiently.

No MOQ

No minimum plans to save your budget. Contact us for more details!